Extraction and FTIR Spectra of Chitin and Chitosan Produced from Periwinkle (Tympanotonos fuscatus) under Differential Decolorization Conditions

DOI:

https://doi.org/10.71148/tjoc/v1i1.7Keywords:

Chitin, Chitosan, Decolorization, Extraction, FTIR, PeriwinkleAbstract

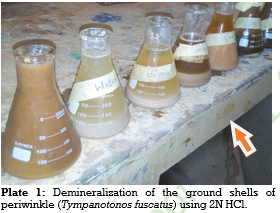

This study aimed to extract and analyze chitosan sourced from periwinkle (Tympanotonos fuscatus) under differential decolorization conditions. Chitin was extracted from the shells of periwinkle (Tympanotonos fuscatus). The pulverized shells underwent demineralization with 2M HCl, deproteination using 1M NaOH, and decolorization to extract chitin. For chitosan extraction, deacetylation was performed with 40 % NaOH. Five solvents: 0.1 % hypochlorite, 1 % acetone, and 1 % ethanol - were employed to eliminate residual pigments from the chitin. FTIR analysis was conducted to examine structural variations resulting from the different decolorization treatments. The chitin yield varied between 51.70 % and 70.9 %, while the chitosan yield ranged from 28.04 % to 48.11 %. The degree of deacetylation was found to be between 46.3 % and 63.5 %, with the combination of acetone and ethanol yielding the lowest degree of deacetylation at 46.3 %. The FTIR spectrum of chitin extracted from periwinkle shells exhibited absorbance bands at approximately 3503.7, 2357.5, 1658.7, 1446.2, 1086.5, 886.6, and 678.4 cm⁻¹. These findings confirm that chitin can be effectively produced from periwinkle shells

Downloads

References

[1] Islam, S., Bhuiyan, M.A.R. & Islam, M.N. (2017). Chitin and chitosan: structure, properties, and applications in biomedical engineering. Journal of Polymer Environment, 25:854–866. https://doi.org/10.1007/s10924-016-0865-5

[2] Abd El-Hack, M.E.; El-Saadony, M.T.; Shafi, M.E.; Zabermawi, N.M.; Arif, M.; Batiha, G.E.; Khafaga, A.F.; Abd El-Hakim, Y.M.; Al-Sagheer, A.A. (2020). Antimicrobial and Antioxidant Properties of Chitosan and Its Derivatives and Their Applications: A Review. Int. J. Biol. Macromol. 164: 2726–2744. https://doi.org/10.1016/j.ijbiomac.2020.08.153

[3] Chien, R., Yen, M. and Mau, J. (2016) Antimicrobial and antitumor activities of chitosan from shiitak estipes, compared to commercial chitosan from crab shells. Carbohydrate Polymer, 138(1):259–264.

DOI: 10.1016/j.carbpol.2015.11.061

[4] Chawla, S. P., Kanatt, S. R. and Sharma, A. K. (2015). Chitosan. Polysaccharides, 6:13-19.

[5] Sara, S.G. (2021). A review of the potential of rice husk (rh) and periwinkle shell (paws) in the development of plastic composites. European Journal of Mechanical Engineering Research, 8(1): 1-9. https://doi.org/10.37745/ejmer.2014

[6] Orji, F. N., Egwuonwu, C. C. and Asoegwu, S. N. (2017). The investigation of periwinkle shell rice husk composite as a replacement for granite in concrete. Open Science Journal of Bioscience and Bioengineering,4(1):1–5. http://www.openscienceonline.com/journal/bio

[7] Moniruzzaman, M., Sku, S., Chowdhury, P., Tanu, M. B., Yeasmine, S., Hossen, M. N., Min, T., Bai, S. C. and Mahmud, Y. (2021). Nutritional evaluation of some economically important marine and freshwater mollusk species of Bangladesh. Heliyon, 7(5), e07088.

DOI: 10.1016/j.heliyon.2021.e07088

[8] Morris, J. P., Backeljau, T. and Chapelle, G. (2019). Shells from aquaculture: A valuable biomaterial, not a nuisance waste product. Reviews in Aquaculture, 11(1), 42–57.

DOI: 10.1111/raq.12225

[9] Murphy, J. N. and Kerton, F. M. (2017). Characterization and utilization of waste streams from mollusk aquaculture and fishing industries. Fuels, Chemicals and Materials from the Oceans and Aquatic Sources, 189–227. doi.org/10.1002/9781119117193.ch8

[10] Oyedepo, O. J and E. O. Olukanni (2015). Experimental investigation of the performance of Palm Kernel Shell and Periwinkle Shell as a partial replacement for coarse aggregate in Asphaltic Concrete. Journal of Building Material and Structure, 2: 33 – 40. https://doi.org/10.34118/jbms.v2i2.18

[11] Abdou, E. S., Nagy, K. S., and Elsabee, M. Z. (2008). Extraction and characterization of chitin and chitosan from local sources. Bioresource Technology, 99(5), 1359-1367. DOI: 10.1016/j.biortech.2007.01.051

[12] Kumar, M. Y. and Ravi, A. (2017). Extraction and characterization of chitosan from shrimp waste for application in the feed industry. International Journal of Science, Environment, and Technology, 6(4): 2548 – 2557.

[13] Sarbon, N.M., Sandanamsamy, S., Kamaruzaman, S.F.S. and Ahmad, F. (2015). Chitosan extracted from mud crab shells (Scylla olivicea): physiochemical and antioxidant properties. Journal of Food Sciences and Technology, 52(7): 4266 – 4275. doi: 10.1007/s13197-014-1522-4

[14] Yen, M., Yang. J. and Mau, J. (2009). Physiochemical characterization of chitin and chitosan from crab shells. Carbohydrate polymers, 75(1): 15 – 21. https://doi.org/10.1016/j.carbpol.2008.06.006

[15] Santos, V.P., Marques, N.S.S., Maia, P.C.S.V., de Lima, M.A.B., de Franco, L.O. and de Campos-Takaki, G.M. (2020). Seafood Waste as Attractive Source of Chitin and Chitosan Production and Their Applications. Int. J. Mol. Sci. 21: 4290. https://doi.org/10.3390/ijms21124290

[16] Nessaa, F., Shah, M.D., Masumb, M., Asaduzzamana, S.K., Hossaina M.M. and Jahan. M. S. (2010). A Process for the Preparation of Chitin and Chitosan from Prawn Shell Waste. Bangladesh Journal of Scientific and Industrial Research, 45(4): 323-330. https://doi.org/10.3329/bjsir.v45i4.7330

[17] Khan, T.A., Peh, K.K. and Ch'ng, H. S. (2002). Reporting degree of deacetylation values of chitosan: the influence of analytical methods. Journal of Pharmacy and Pharmaceutical Sciences, 5(3):205-212. PMID: 12553887

[18] Gadgey, K.K. and Bahekar, A. (2017). Studies on Extraction Methods of Chitin from Crab Shell and Investigation of its Mechanical Properties. International Journal of Mechanical Engineering and Technology, 8(2): 220–231

[19] Sambo, R. E., Nuhu, A. A. and Uba, S. (2019). Preparation and Characterisation of Shrimp Waste-Derived Chitin, Chitosan, and Modified Chitosan Films. Nigerian Research Journal of Chemical Sciences, 6: 1 – 18.

http://www.unn.edu.ng/nigerian-research-journal-of-chemical-sciences/

[20] Percot, A. and Viton, C and Domard, A. (2003). Characterization of shrimp shell deproteination. Biomacromolecules, 4:1380–1385. DOI: 10.1021/bm034115h

[21] Mohammed, M.H., Peter, A., Williams, A. and Tverezovskaya, O. (2013). Extraction of chitin from prawn shells and conversion to low molecular mass Chitosan. Food Hydrocolloids, 31: 166-171.

https://api.semanticscholar.org/CorpusID:93341552

[22] Varma, R., Vasudevan, S., Chelladurai, S. and Narayanasamy, A. (2022). Synthesis and Physicochemical Characteristics of Chitosan Extracted from Pinna deltoids. Letters in Applied NanoBioScience, 11(4): 4061 – 4070. https://doi.org/10.33263/LIANBS114.40614070.

[23] El-Knidri, H., Belaabed, R., Addaou, A., Laajeb, A. and Lahsin, A. (2018). Extraction, chemical modification, and characterization of chitin and chitosan. International Journal of Biological Macromolecules. 120: 1181-1189. https://doi.org/10.1016/j.ijbiomac.2018.08.139

[24] Kovaleva, E. G., Pestov, A.V., Stepanova, P. D. and Molochnikov, L. S. (2016). Characterization of chitin and its complexes extracted from natural raw sources. 1772(1):050007-. Doi: 10.1063/1.496457

[25] Akpan, E.I., Gbenebor, O.P. and Adeosun, S.O. (2018). Synthesis and characterization of chitin from periwinkle (Tympanotonus fusatus (L.)) and snail (Lissachatina fulica (Bowdich)) shells. International Journal of Biological Macromolecules, 106: 1080–1088. DOI: 10.1016/j.ijbiomac.2017.08.106

[26] Pecora, J.D., Sousa-Neto, M.D. and Estrela C. (1999). Soluções irrigadoras auxiliares do preparo do canal radicular. In: Endodontia - Princípios biológicos e mecânicos. Estrela C, Figueiredo JAP. Eds. São Paulo: Artes Médicas;. Pp 552-569.

[27] Puvvada, Y. S., Vankayalapati, S. and Sukhavasi, S. (2012). Extraction of Chitin from Chitosan from Exoskeleton of Shrimp for Application in the Pharmaceutical Industry. International Current Pharmaceutical Journal, 1(9):258-263. DOI: https://doi.org/10.3329/icpj.v1i9.11616

Downloads

Published

Issue

Section

License

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.